Domino Printing Sciences has launched the latest editions to its successful D-Series range of scribing lasers including the introduction of a superior ‘i-Tech 10’ scan head offering greater production efficiencies and the launch of a new ‘Red Tube’ variant for Polypropylene (PP) applications.

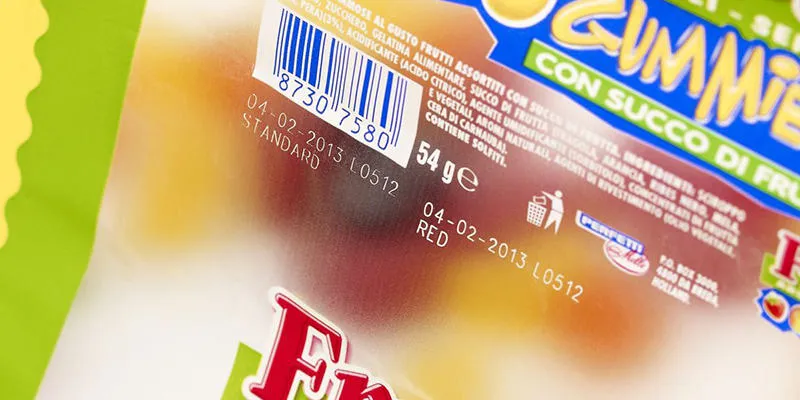

The new D320i 10 Red Tube version has been developed specifically to deliver high precision coding onto PP and PP-layered materials such as film and foil, where standard lasers can blister the substrate and distort the code.

In addition, Domino’s improved superior i-Tech 10 scan head has advanced mirror control for faster performance in high speed production lines. Depending on the application, the new i-Tech 10 scan head can offer higher energy density for hard to mark materials of up to 26% as well as achieving production speeds of up to 31% faster than previous models.

Where standard laser applications can cause melting and blistering of the PP substrate or show a low contrast producing poor quality coding, Domino’s new D320i 10 Red Tube variant operates at a 10.2µm wavelength ensuring a better reaction of the PP plastic material to the laser beam than with the standard wavelength. The increased absorption of the laser beam eliminates code distortion and results in a high quality, high precision marking for optimum contrast and clarity of text, graphics, linear and 2D datamatrix codes.

This new ‘red tube’ option produces the highest quality coding onto both PP films and hard plastics, which are particularly suited for applications in the food, beverage, cosmetics and life Sciences sectors.

The addition of the ‘red tube’ variant and superior performance i-Tech 10 scan head are the latest in a series of ongoing developments to the D-Series range of scribing lasers, which have been developed by Domino’s team of laser experts based at its Laser Centre of Excellence in Hamburg, Germany.

Erik Wimmer, Product Manager for the D-Series at Domino says, “Our expert team of scientists are constantly looking at ways to push the boundaries of laser technology to maximise coding output onto a range of substrates. It is this constant investment in research and development that has enabled us to introduce these latest variants to our D-Series range, which not only benefits the end customer in terms of clearer labelling and coding, but also seeks to deliver optimal production efficiencies for manufacturers.”

Domino’s D-Series range of scribing lasers operate from low to high production line speeds and comprises the D120i (10-watt output), the D320i (30-watt output) and powerful D620i (60 watt output) models.

The compact design and small footprint of the lasers enables the D-Series models to be easily integrated into the smallest of spaces within the production line. In addition, all variants incorporate Domino’s i-Tech intelligent Technology aimed at reducing downtime and increasing production efficiencies and output. Operators benefit from Domino’s intuitive and flexible remote or web-based TouchPanel interface that can be run on any industrial PC. For ultimate flexibility, the D-Series lasers can also be controlled via the customer’s own production line interfaces.

All models are available in pharmaceutical versions that comply with 21-CFR part 11 and GAMP. Features include unique user passwords and change reporting, and coders can be supplied with validation packages to ensure systems are tested and proven to the highest standards. The D-Series is also compatible with the Codentify® solution, which prints a unique 12 digit code to provide product authentication and enable fiscal recovery.